Transform Data into Value

As a prominent multinational chemical company, BASF is known for its innovation across numerous sectors, including Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. To drive this innovation, the company puts a strong emphasis on “Verbund,” the intelligent interlinking of research and development, production plants, energy flows and infrastructure. This notion of combined cooperation trickles all the way down to the company’s R&D data processes. R&D data are expected to be integrated, understood, and used to garner insights that drive innovation.

“High quality data is the basis for good business decisions,” explains Dr. Joachim Dickhaut, Senior Principal Scientist in BASF’s Agricultural Research Division, which develops fungicides, herbicides, insecticides and biological crop-protection products, seeds and seed-treatment products, as well as digital solutions and services. Unfortunately, meeting this expectation for data-driven decision making was becoming increasingly challenging for Dr. Dickhaut and his team. The team’s existing R&D infrastructure was struggling to fully support the team’s complicated R&D workflows and the vast volumes of complex data flowing from those workflows.

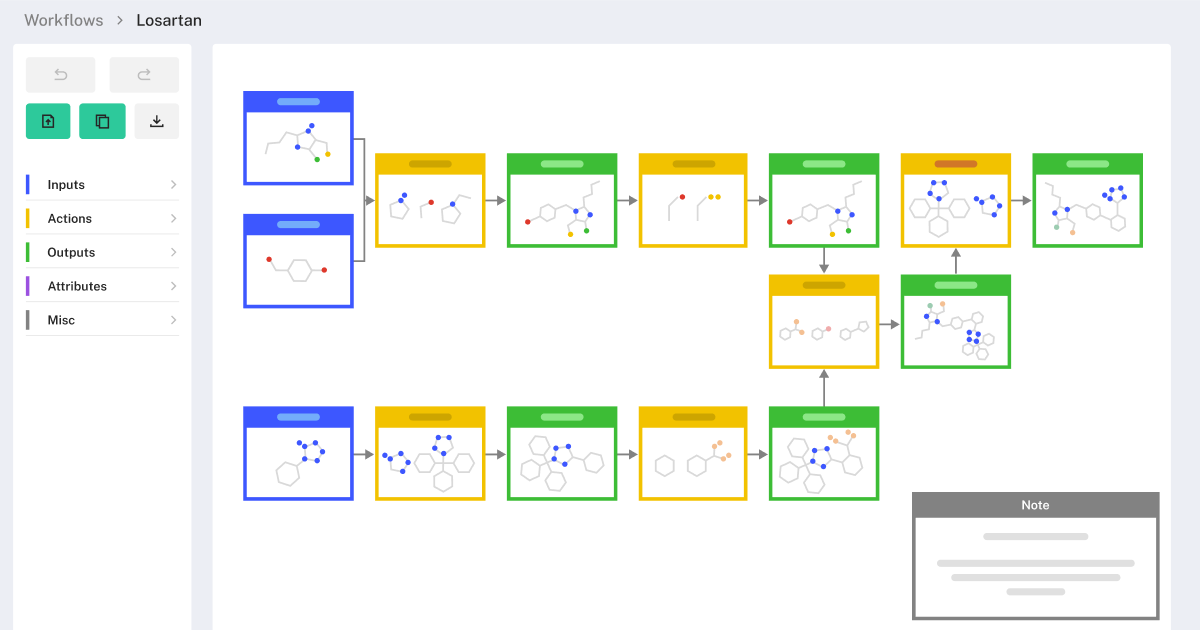

Broadly speaking, the team’s workflows follow a standard design-make-test-analyze (DMTA) workflow. Under this approach, researchers first uncover promising molecules to explore with the aid of a vast molecular-property database and machine learning tools, which they call “Quriosity.” They then iterate through key R&D steps, including experiment planning, sample creation, testing, and scientific analysis. Each of these steps creates huge volumes of data that need to be collected, organized, and analyzed. With the team’s existing R&D infrastructure, this was often a frustrating, cumbersome endeavor in which researchers struggled to transform data into valuable insights that drive innovation. A change was needed.

The BASF Agricultural Research Division team began the search for a solution that would support their end-to-end workflow and data needs, while also offering top-notch flexibility, performance and usability. Dotmatics was the perfect fit. The team chose to adopt:

Dotmatics' multimodal electronic laboratory notebook to capture experimental data across various complex workflows.

Dotmatics' scientific data management platform to aggregate and manage data from different workflows and sources.

Dotmatics' data discovery tools to find, combine, and make sense of data and inform decisions.

These new solutions needed to be rolled out to a broad range of users, including bench scientists, senior scientists, and lab leaders, who all have unique ways of working with the team’s R&D data. BASF team leadership felt a phased-change plan would help them rollout Dotmatics solutions without disrupting existing workflows. They worked with Dotmatics to develop a “Data to Value” (D2V) initiative that was broken into three key projects:

Project 1 – Data Visualization: A move from spreadsheet-based analysis to a Dotmatics solution built specifically for chemical data analysis helped BASF team members look at their data in many different ways to drive deeper understanding and make better data-driven decisions.

Project 2 – Search & Data Aggregation: Dotmatics’ powerful scientific search solution was rolled out to help BASF team members better access their vast data warehouse of R&D data from all their various sources, legacy projects, and diverse teams.

Project 3 – Electronic Laboratory Notebook (ELN) Rollout: Dotmatics ELN, with web-based data aggregation capabilities, was adopted to support the wide range of complex experiments being conducted by different team members.

Each project was a great success. The entire BASF Agricultural Solutions division is better positioned to innovate thanks to enhanced access to R&D data and data-analysis solutions. In particular:

Lab and bench scientists can not only quickly capture their experimental workflows and results, but they can also easily find, share, and use R&D data to further innovate.

Project and team leaders, as well as data scientists, can gain insights not previously possible thanks to unhindered access to high-quality, curated, cross-project data and advanced analytics and automation tools.

IT team members can more easily keep pace with user needs by leveraging web-based updates and APIs.

As Dr. Dickhaut summarized, “Scientists need the ability to do a variety of searches, looking over multiple experiments or across many projects, if they have required permissions.” Dotmatics delivered.

Next Steps

Read the full BASF case study: Dotmatics Implements ‘Data to Value’ Initiative with BASF Agricultural Solutions

Request a Demo: Accelerate your chemicals and materials research with Dotmatics R&D workflow software. Speak with a product expert so we can provide you with a demo based on your specific needs.